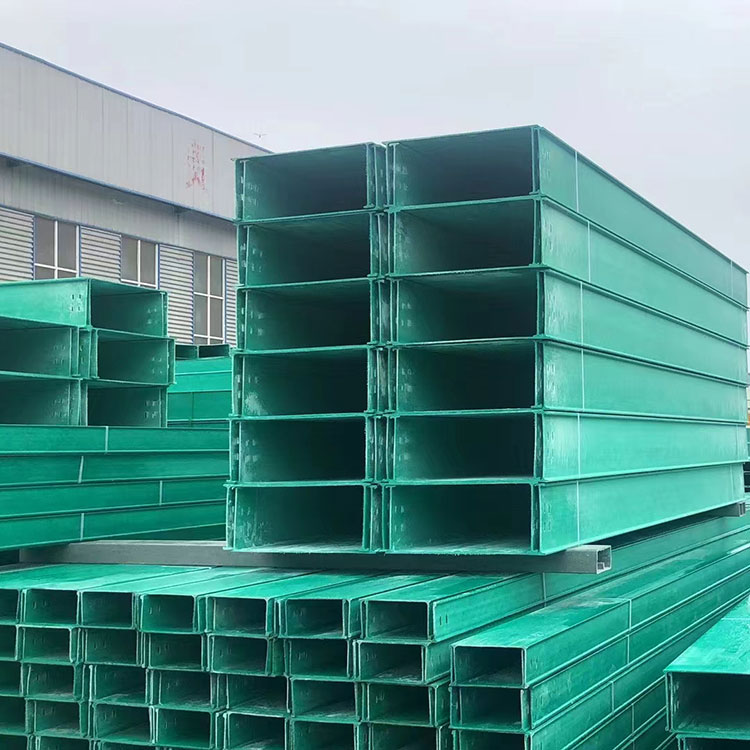

Hebei Tengjun FRP cable tray is composed of glass fiber reinforced materials and resin matrix. It is used to support and protect cables, wires and other lines:

1. It has high strength and rigidity and can withstand a certain load.

2. It has good corrosion resistance and can be used in corrosive environments such as acids, alkalis, and salts.

3. Good insulation performance to ensure electrical safety.

4. Lightweight and high-strength, easy to install and carry.

5. Beautiful and elegant, the color can be customized.

FRP cable tray technology:

1. Raw material preparation: Select appropriate fiberglass and resin.

2. Mold making: Make molds according to product specifications.

3. Ingredients: Mix resin, curing agent, etc. in proportion.

4. Impregnation: Impregnating glass fiber in resin.

5. Forming: Forming in the mold.

6. Curing: Curing after a certain period of time.

7. Trimming: remove burrs, etc.

8. Testing: Carry out quality testing.

FRP cable tray model:

Common models are available in a variety of sizes and specifications to suit different wiring needs.

FRP cable tray style:

It can be tray type, trough type, ladder type, etc., with simple and beautiful appearance.

Advantages of FRP cable tray:

1. Corrosion resistance: Can resist the erosion of chemical substances.

2. Light weight and high strength: light weight but sufficient strength.

3. Good insulation: ensure electrical safety.

4. Anti-aging: Stable performance for long-term use.

5. Good weather resistance: adaptable to various climate conditions.

6. Strong designability: can be customized according to needs.

Advantages of fiberglass bridge installation:

1. Excellent comprehensive performance to meet a variety of needs.

2. Easy to install and reduce construction costs.

3. Long life and reduced maintenance costs.

4. Can be customized to adapt to different wiring environments.

5. Beautiful and elegant, harmonious with the surrounding environment.

FRP cable tray have a wide range of applications, including but not limited to the following fields:

1. Industrial plant: Provide support and protection for cables of various equipment.

2. Commercial buildings: electrical wiring in shopping malls, office buildings, etc.

3. Power system: used for laying transmission lines.

4. Communication facilities: Ensure the safety of communication cables.

5. Chemical enterprises: Resistant to chemical corrosion.

6. Subway tunnel: adapted to special environments.

7. Marine engineering: Resistant to seawater corrosion.

8. Sewage treatment plant: can be used in humid environments.

9. Airport terminal building: meet the laying needs of a large number of electrical lines.

10. Highway: used for the layout of cables such as traffic signals.

11. Data center: ensure the orderly laying of a large number of data lines.

12. Mining enterprises: work stably under harsh conditions.